I wrote about my sit down and interview with Chris Wellise, HPE’s Chief Sustainability Officer yesterday. He was joined by his colleage Matthias Röse, HPE’s Chief Technologist for Mfg, Auto and IoT, for a round table session with me and the other influencers that were invited by HPE to #HM19 at the Hannover Messe.

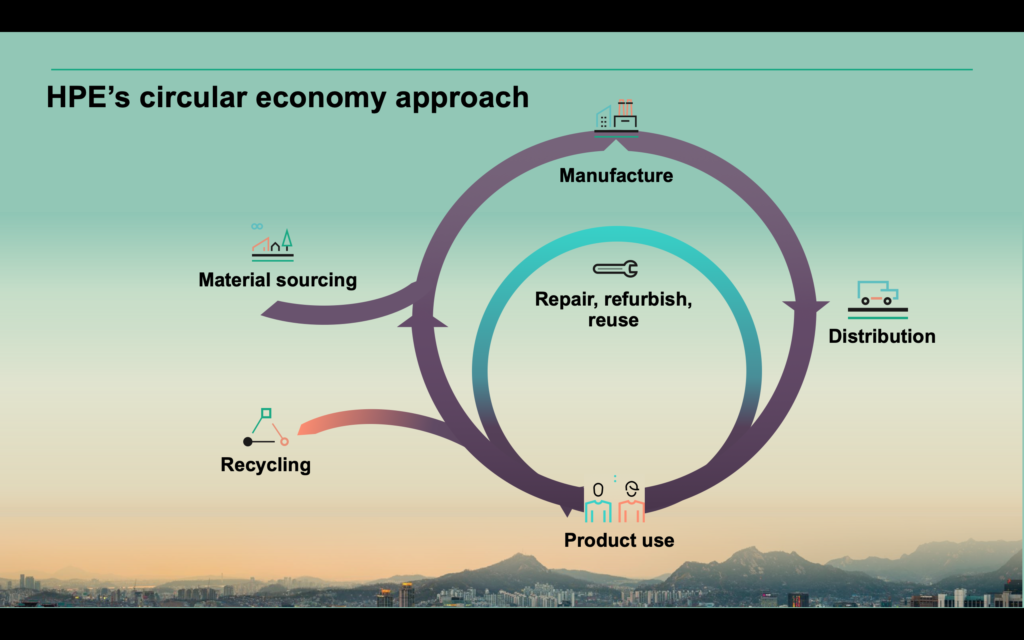

Between Chris and Matthias they expanded on HPE’s alternative to the typical “take, make and dispose” economy to think circular and closed loop. They talked about the amount of greenhouse gasses used in the extraction, manufacturing and production processes and how they think in terms of material resourcing designed to minimise its impact on the environment. As explained in the last post, HPE design their products for recyclability and end of use management, with an impressive 89% remanufactured and marketed to new customers. To put some numbers against that, it equates to their renewal centres processing £58m worth of product a year consisting of 1.7m data centre products and 2.3m workplace products. That’s a huge saving in energy and resources that don’t have to be extracted and consumed. Apart from saving the planet, the business case for doing this balances the potential for higher commodity prices as resource scarcity and volatility hits, with the resultant supply disruptions that would cause, along with the potential for ever tightening regulation, balanced against the opportunity for reduced costs, generating new revenues, improved competitiveness and a more resilient supply chain.

However, 60% of the environmental impact of technology products comes in the use phase. HPE believes it’s critical to be designing for efficiency to have the biggest impact. That means thinking in terms of materials innovation. It means products like HPE’s Synergy providing software defined storage, network and compute in one block instead of a standard rack mounted server, and that means less impact and a better utilisation rate. Sadly most data centres are often over provisioned with server set ups 80% under-utilised – Matthias talked about zombie servers idling away, and I rather like that term. HPE are on a mission to share applications on a block, and provide a better utilisation rate. Virtualisation and containerisation is the first step, but they talked in terms of using the whole chain of IT as a process with software defined architecture. You should be paying only for what you use, what you need. Interestingly, with their Greenlake product, that extends the OpEx pay-as-you-go consumption-based approach to on-premise hardware. That, in turn, extends HPE’s hybrid-cloud credentials and means better cashflow for their customers, and the ability to manage the peaks more easily. Capacity on demand in your data centre, as well as the public cloud.

This approach to infrastructure goes hand in hand with the shift in focus of data and processing moving to the edge, where we need solutions that provide compute power at or near the source of where the data is generated by a mobile device, a machine on the shop floor or a sensor. This is vital for supporting IoT, for the requirements of autonomous vehicles in the field, or the needs of the smart city. Gartner predicts that 75% of data will computed at the edge rather than in the data centre by 2025, and maybe it’s coming even sooner than that!

Matthias was talking in terms of extending the sustainability arguments to closed loop manufacturing, taking the data from manufacturing shop floor systems, apply data analytics and AI to identify resource leakage. Using predictive maintenance for identifying and preventing failures means the firm doesn’t need to build new, replacement product. He told us about an undisclosed car manufacturer that he is currently working with. For a luxury model with an automatic close function for the boot they are tracking usage, how often is that close button actually pressed. How robust do the mechanisms and the motors driving the boot door actually need to be? That may sound trivial, but I liken it to Sir Dave Brailsford’s sports science of marginal gains. He transformed UK cycling by focusing on every element of the process from the cyclist, to her clothing, to the bike, to the track and looking for 1% gains in each piece of equipment used, each process step, and particularly looking for undiscovered areas to make a small difference. All those tiny gains eventually add up to significant change, and the increase in effectiveness gave the team a large haul of Olympic and World Championship Gold medals. That’s exactly the way those marginal gains for the automotive manufacturer will add up to significant efficiencies and sustainability, and a more successful HPE customer.

They talked about how the repair shops generally not owned by manufacturers, but can be connected better. They mentioned Daimler and their leadership 2020 programme helping them become agile. They mentioned blockchain implementations in the context of making data more secure, and the idea of sharing more data from the car. That could mean monetisation opportunities, but more likely it will be providing inputs to applications like Google Maps or Waze for traffic patterns, or route planning or emergencies.

There is a change in approach in the company from 3 years ago where within IoT they were trying to do everything. Today their strategy is an open ecosystem approach with more choice, and a range of the right partners for specific parts of the processes. They are bringing IT and OT (Operational Technology) together. Matthias has a background in Siemens before HPE, and they could argue that they had IoT 25 years ago. Except it just wasn’t as open to the outside as Industrial IoT is today. They are building in safety and security, gathering more data, more knowledge, applying AI to detect issues, deviate the data flows, eliminate challenges, increase the uptime – they bring a lot to the table. It’s a totally different mindset that combines lean manufacturing, and what I suggested as “marginal gains” in to OEE or Overall Equipment Effectiveness. It’s taking sustainability a step further.

Check back here for more content like this, and contact us if you want to find out more about digital manufacturing.

Disclosure: HPE paid my expenses for the trip to HMI 2019 as part of their influencer programme.